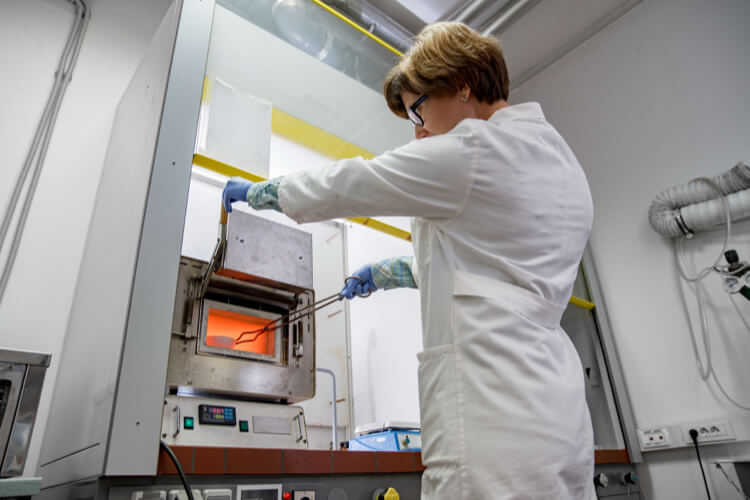

Sintering Furnaces

Sintering furnaces provide controlled high-temperature environments for industrial and laboratory material processing. Sentro Tech builds each unit to meet the thermal demands of sintering metals, ceramics, and composites accurately and consistently.

Learn More About Our Sintering Furnaces

The STT 1700°C (3092°F) is an economical sintering tube furnace perfect for low cost labs and the 3D metal printing industry. Furnace provides one of the best cost-to-value ratios on the market for both laboratory and small-scale production applications. Get an unbeatable price for the STT sintering tube furnace from Sentro Tech.

The STV 1600C vacuum and controlled atmosphere furnace is our versatile, low-cost sintering furnace perfect for 3D metal printing, laboratories, and production applications up to 1600°C. The Sentro Tech STV sintering furnace provides one of the best cost-to-value ratios on the market for 3D printing, laboratory, and small-scale production applications.

The STHV 1400C vacuum and controlled atmosphere furnace is our versatile, low-cost sintering furnace perfect for 3D metal printing, laboratories, and production applications up to 1400°C. The Sentro Tech STHV sintering furnace provides one of the best cost-to-value ratios on the market for 3D printing, laboratory, and small-scale production applications.

The STHV 1700C vacuum and controlled atmosphere furnace is our versatile, low-cost sintering furnace perfect for 3D metal printing, laboratories, and production applications up to 1700°C. The Sentro Tech STHV sintering furnace provides one of the best cost-to-value ratios on the market for 3D printing, laboratory, and small-scale production applications.

Applications and Industries for Sintering Furnaces

Sintering furnaces support critical processes in sectors that require stable, high-temperature environments for material consolidation and treatment.

Professionals use these systems in production, testing, and research settings where control and repeatability directly affect output quality and performance.

Some of the most common applications of sintering furnaces include:

- Powder metallurgy

- Metal injection molding

- Ceramic component fabrication

- Additive manufacturing post-processing

- Material densification and grain structure refinement

Industries using these furnaces range from aerospace and electronics to medical device manufacturing and advanced materials development. Each environment depends on precise thermal control to meet performance standards.

Sintering Furnace Specifications

Sentro Tech’s standard furnace model specifications include (but aren’t limited to) the following:

- 1400°C to 1700°C Maximum operating temperatures

- Chamber dimensions up to 36” x 36” x 36”

- PID Temperature Controller with data recording and computer communication

- Can be operated in air, vacuum, and argon/nitrogen atmosphere

- Can be operated in a partial vacuum and positive vessel pressure

- Data recording, computer communication

- Quick heat-up and cool-down

- Excellent temperature accuracy and uniformity

- Energy-efficient ceramic fiber insulation

- Double-shell design to ensure low outside temperature

- Automatic shut-off safety feature

- One-year limited warranty on electronic parts

Sintering Furnaces FAQs

Learn more about sintering furnaces through our FAQs.

How long does a typical sintering cycle take in a high-temperature furnace?

Sintering cycle times vary depending on the material, part size, and temperature requirements. A typical cycle can last several hours to over a full day, including ramp-up, hold, and cool-down periods.

What maintenance is required for a sintering furnace?

Regular maintenance includes inspecting heating elements, checking thermocouples, monitoring insulation, and cleaning chamber surfaces. For vacuum sintering furnaces, users should also monitor vacuum seals and pumps.

Can sintering furnaces be used with inert gases like argon or nitrogen?

Yes. Many sintering furnaces, especially vacuum and custom high-temperature models, support inert gas atmospheres. This allows for better control over chemical reactions during sintering, especially when processing reactive metals or materials that require non-oxidizing conditions.

Get Expert Help Choosing the Best Sintering Furnace for Your Operations

Contact Sentro Tech to speak with an engineer about your process requirements. As leading sintering furnace manufacturers, we’ll help you choose the right sintering furnace for your application, timeline, and facility.

Request a quote, request technical specs, or ask about custom options. Let’s build a system that truly works for your operation.

Related Articles

Address: 21294 Drake Rd., Strongsville, OH 44149 Phone: (440) 260-0364

Copyright Sentro Tech