Power Generation Equipment

High Temperature Furnace

Industrial furnaces are the central foundation for a wide variety of thermal power generation operations. During this process, the power plant uses a furnace or furnace boiler to convert water into high-pressure steam. This steam then flows into the turbine, resulting in the creation of kinetic energy. A generator, linked to the turbine, uses this kinetic energy to create electricity.

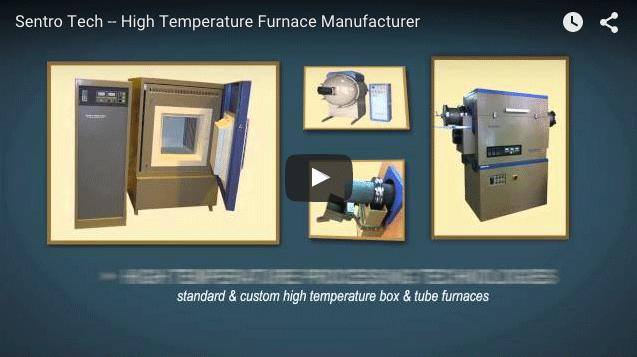

In order to match the exacting dimensions and tight tolerances of this precise process, Sentro Tech offers a full catalog of furnaces and equipment for efficient power generation. For example, the box furnace is engineered to ensure the consistent and accurate temperature control needed to create the ideal pressure environment. Vacuum and atmosphere controlled furnaces allow for a multi-atmosphere process in one cycle with accurate air/inert gas flow rate control. Finally, alumina tubes and silicon carbide tubes feature high flexural strength and excellent thermal shock resistance.

High Temperature Furnaces and Equipment for Power Generation

• Box Furnaces: Standard and Custom Box furnaces are available in a wide range of configurations and temperature ranges.

• Vacuum and Atmosphere Controlled Furnaces: Vacuum and Atmosphere Controlled furnaces facilitate the firing cycles where atmosphere conditions may vary during operation cycle.

• Alumina Tubes: With 99.5% to 99.8% high purity, Sentro Tech’s Alumina tubes offer elevated temperature stability.

• Silicon Carbide Tubes: Silicon Carbide tubes deliver a tight dimensional control, reducing or eliminating the need for after-sintering.

Contact a Sentro Tech representative today to learn how our high temperature furnace equipment and parts can match your power generation needs.