Muffle Furnace Buying Guide: Assessing Muffle Furnace Uses, Working Principles & Important Benefits

Questions? Contact Us!

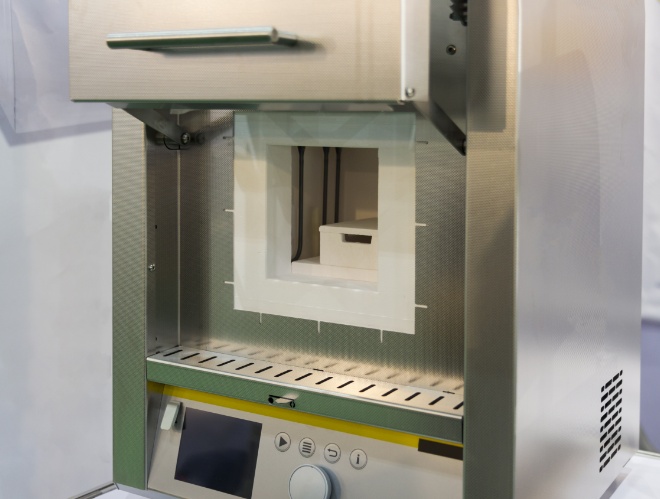

What is a Muffle Furnace?

A muffle furnace allows rapid high-temperature heating, recovery, and cooling in self-contained, energy-efficient cabinets. A muffle furnace separates the object to be heated from all byproducts of combustion from the heat source. In modern electrical furnaces, radiation or convection energy applies heat to a chamber using a high-temperature heating coil inside insulated material. The insulating material effectively acts as a muffle, preventing heat from escaping.

Common Muffle Furnace Uses

Muffle furnaces are commonly used for heating in industrial and laboratory settings. Today’s modern electrical muffle furnaces heat by conduction, convection, or blackbody radiation processes. This process eliminates the creation of combustion byproducts common in non-electric muffle furnaces of the early 20th Century.

Additionally, advances in materials for heating elements, such as the molybdenum disilicide, can produce working temperatures up to 1,800 degrees Celsius (3,272 degrees Fahrenheit). This high-temperature muffle furnace function facilitates more sophisticated metallurgical applications like debinding, sintering, and end-to-end processes in metal injection molding.

Muffle Furnace Applications

Muffle furnaces now use technology and design to achieve greater control of temperature uniformity and isolate heated materials from combustion contaminants. This makes muffle furnaces ideal for ashing samples, heat-treating applications, and materials research.

Based on this critical muffle furnace working principle, industrial manufacturers and laboratory environments commonly use muffle furnaces for high-temperature applications. These muffle furnace applications include:

- Melting glass

- Creating enamel coatings

- Technical ceramics

- Soldering and brazing

Benefits of a Custom Muffle Furnace for Unique Processes

For unique applications or productions, consider a custom-built high-temperature muffle lab furnace. You can build a custom high-temperature muffle furnace solution to meet the exact specifications or requirements for your application or production. Custom equipment enables the success of your product development and testing process outcomes.

Sentro Tech Muffle Furnaces Deliver Reliable Results

A family-owned company based in Northeast Ohio, Sento Tech manufactures high-temperature industrial and lab furnaces for a variety of industries and applications. Sentro Tech started as a designer and manufacturer of Molybdenum Silicide heating elements and related heating panels. In 2004, the company started manufacturing custom laboratory and production furnaces to meet specific application and production needs.

Sentro Tech’s Muffle Furnace Maintenance Advantage

Sentro Tech provides high-quality technical support and service for our customers. When it comes to your muffle furnace maintenance needs, we have all the resources you need to achieve quick solutions. We manufacture and ship products directly from our Ohio-based headquarters so you can receive the replacement parts you need quickly. We stock all replacement parts—including heating elements, thermocouples, and other essential electric parts— on-site, with all options ready to ship at your earliest convenience.

We proudly serve our customers and offer a 100% satisfaction guarantee on all our high-temperature muffle furnaces. Contact a Sentro Tech sales representative if you have specific questions about our heating products or your production needs.

Address: 21294 Drake Rd., Strongsville, OH 44149 Phone: (440) 260-0364

Copyright Sentro Tech