Why Industrial Furnace Maintenance Matters More Than You Think

When you're in the thick of production, it's easy to treat industrial heating maintenance like background noise — something you'll "get to" after the next cycle. But skipping or delaying regular maintenance doesn't just risk a drop in performance; it fast-tracks wear and tear, invites costly breakdowns, and shortens your equipment's life span. For high-precision processes like heat treatment, even a minor miscalibration can lead to inconsistent results or failed batches. And in industries where consistency equals profit, that's a gamble no one wants to take.

Proactive industrial heating furnace maintenance unlocks your system's full potential. Clean components operate more efficiently. Calibrated sensors deliver more accurate readings. And when everything's running like it should, you can push your system harder without fear of an unexpected shutdown. It's the kind of peace of mind you can't put a price on, but that definitely saves money in the long run.

Key Maintenance Tasks to Keep Your Furnace Running Hot

Think of your industrial furnace like a high-performance engine: it'll treat you right if you treat it right. Staying ahead with routine heat treatment furnace maintenance helps you dodge emergency repairs, keep temps consistent, and extend the life of your investment. Here's a breakdown of the most critical maintenance tasks every heat treatment or industrial furnace owner should have on their radar.

1. Inspect and Calibrate Temperature Controls

This is where it all starts. If your thermocouples, controllers, or sensors are off by even a few degrees, you could be running out of spec without knowing it. Make it a habit to test and calibrate these components regularly, and always after any major downtime or repairs.

2. Clean Heating Elements and Insulation

Dust, debris, and process residue build up faster than you'd think. Not only can that gunk insulate your elements and raise your energy bills, but it also puts unnecessary stress on your heating system. Periodic cleanings can make a big difference in efficiency and longevity.

3. Check Door Seals and Insulation Integrity

Even a small air leak can throw off your whole heating profile. Worn-out door gaskets or cracked insulation panels lead to heat loss, longer cycle times, and uneven processing. Check for physical damage, warping, or softness and replace as needed.

4. Monitor Electrical Connections and Power Supply

Loose terminals and frayed wiring aren't just maintenance concerns; they're safety hazards. A quick voltage and amperage check, paired with visual inspections, can help prevent surprise shutdowns or, worse, electrical fires.

Pro Tip: Preventative Maintenance = Profitable Operation

Here's the truth no one wants to admit: most industrial furnace repair calls could've been avoided with a solid preventative maintenance plan. Regular tune-ups don't just stop issues before they start; they optimize everything. Better heat distribution. Faster ramp-up times. Less wasted energy. It's the easiest way to get more out of your existing setup without expensive upgrades. Prevention saves you time and money.

Signs Your Furnace Needs Maintenance (Or Might Be Headed for Trouble)

Even if your system isn't throwing alarms, there are subtle clues that something's not quite right. Catching these early can mean the difference between a quick fix and a full-blown shutdown. If you're noticing any of these red flags, it's time to pause and inspect:

- Uneven or inconsistent heating zones

- Longer cycle times than usual

- Strange noises (buzzing, humming, or popping)

- Sudden spikes in energy consumption

- Burnt-out elements more frequently than expected

- Odors or smoke during ramp-up

Bottom line: Don't wait for a breakdown. If your furnace is acting even a little out of character, schedule an inspection before things spiral.

Keep Your System Stocked and Ready

Need a replacement part? SentroTech's components have you covered. From specialized temperature control systems to industrial furnace replacement parts, you'll find exactly what you need to stay up and running: no guesswork, no delays.

Shop Furnace Parts & EquipmentSentroTech: High-Temperature Furnace Manufacturer

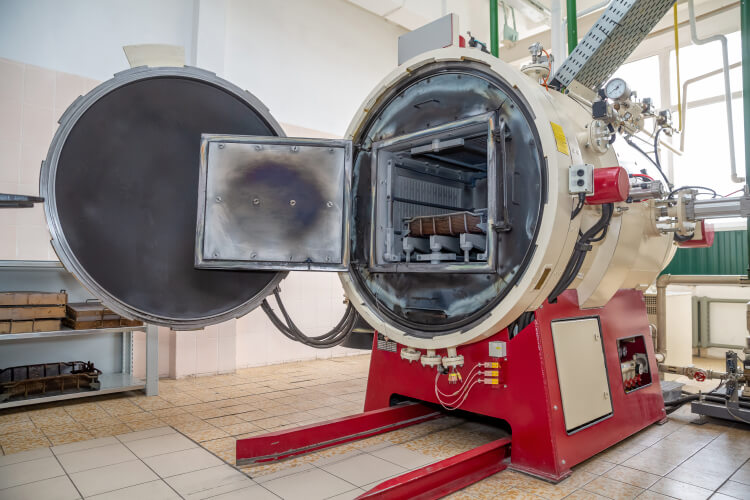

SentroTech Corporation provides high-temperature box and tube furnaces for various applications, including small lab furnaces, large production kilns, or custom-designed solutions to meet your needs.

Time to Replace an Old Workhorse?

Even the best-maintained systems reach the end of the line. When your heating furnace starts costing more to keep alive than it's worth, it's time to upgrade. That's where SentroTech comes in. With reliable, high-performance industrial furnaces built for demanding environments, we'll help you keep the fire going stronger, faster, and more efficient than ever.

Request a QuoteFAQs: Industrial Furnace Maintenance

Here are some quick answers to the most common questions folks have when it comes to maintaining or replacing their industrial heating systems. Don't see your question here? Feel free to contact us for more info.

What should I do if my industrial furnace stops working suddenly?

Stay calm and cut the power. Safety comes before troubleshooting. Check for obvious issues like tripped breakers, blown fuses, or disconnected wiring. If you don't see anything on the surface, it could be an internal component failure: heating elements, thermocouples, or control modules are common culprits. If you're facing repeated shutdowns, it might be a sign your furnace is on its last legs. In that case, it's worth looking at replacement options rather than just patching it up.

When should I consider upgrading my furnace instead of maintaining it?

If your furnace is over 10-15 years old, needs constant repairs, or can't hold temperature like it used to, it's probably time to upgrade. Another red flag? If replacement parts are hard to find or the system isn't meeting production specs. Investing in a new, energy-efficient furnace can pay for itself fast, especially if you're running longer cycles or operating at high temps. SentroTech offers a range of modern systems that are ready to take on the heat.

Are there specific regulations for industrial furnace maintenance?

Yes, depending on your industry and location, you may need to follow OSHA, EPA, or NFPA guidelines related to industrial heating equipment. These could involve ventilation, emissions, temperature control, or fire prevention. Regular inspections and documentation are often required, especially in labs or manufacturing facilities. While SentroTech doesn't offer maintenance services directly, our team can help you select equipment that supports compliance from day one.